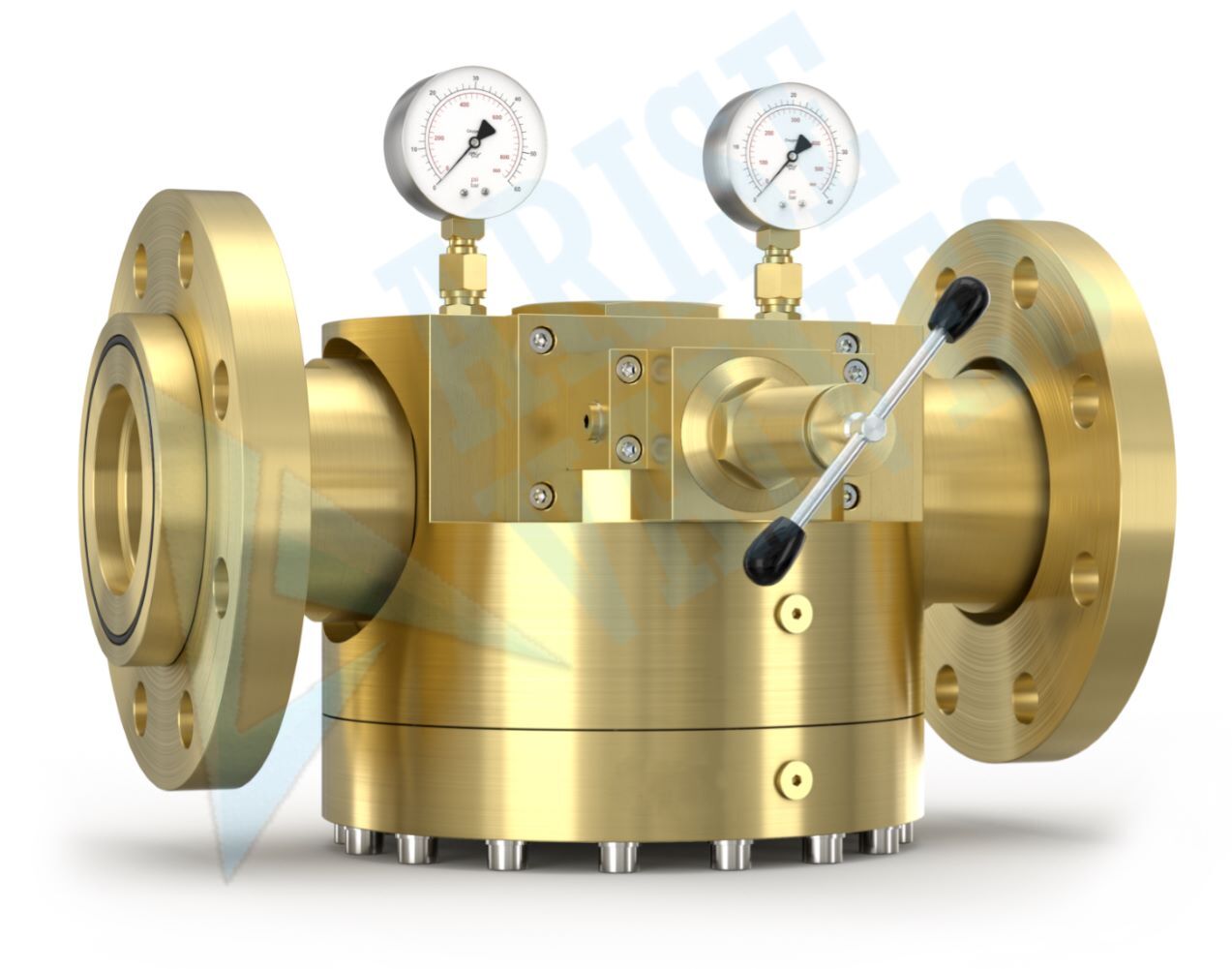

Back pressure regulator

Back Pressure Regulator

A back pressure regulator maintains a set pressure upstream by relieving excess pressure, ensuring stable operation in fluid, gas, and steam systems. It helps prevent system overpressure and maintains process efficiency.

Key Features:

- Precise Pressure Control – Regulates upstream pressure by releasing excess flow.

- Durable & Corrosion-Resistant – Made from stainless steel, brass, or engineered plastics.

- Adjustable Setpoint – Allows fine-tuning for specific process requirements.

- Leak-Proof & Reliable Sealing – Ensures safety and consistent pressure regulation.

- Handles Various Media – Suitable for gases, liquids, and steam applications.

Application:

- Industrial Process Control – Maintains stable pressure in manufacturing systems.

- Gas Distribution Networks – Prevents overpressure in supply lines.

- Chemical & Pharmaceutical Processing – Ensures precise pressure in sensitive reactions.

- Hydraulic & Pneumatic Systems – Regulates backpressure for smooth operations.

- Oil & Gas Industries – Controls wellhead and pipeline pressure.

Advantages:

- Prevents System Overpressure – Protects equipment from pressure spikes.

- Enhances Process Efficiency – Maintains optimal flow rates and system stability.

- Extends Equipment Life – Reduces wear on downstream components.

- Minimizes Product Waste – Ensures precise control over fluid or gas flow.

- Reliable Performance – Works continuously with minimal maintenance needs.

Maintenance & Safety Tips:

- Inspect Regularly for Leaks – Ensures consistent operation and safety.

- Monitor Pressure Readings – Prevents fluctuations that could affect system efficiency.

- Clean Valves & Diaphragms – Removes debris to prevent clogging.

- Check for Wear & Tear – Replace seals and diaphragms as needed.

- Follow Installation Guidelines – Ensures proper functioning and longevity.