Low pressure regulator air

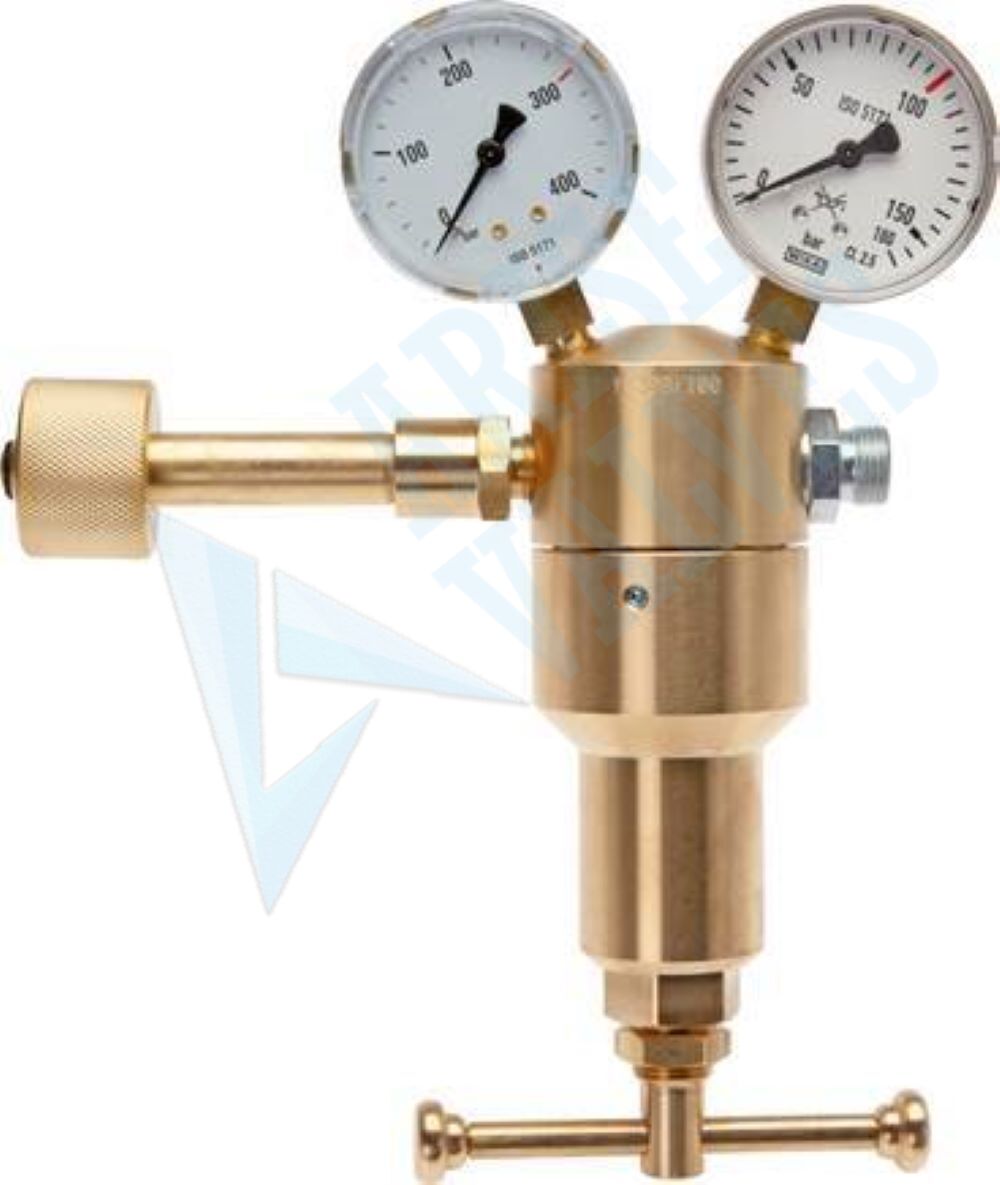

Low Pressure Air Regulator

A low-pressure air regulator is designed to control and maintain air pressure at lower levels, ensuring safe and efficient operation in pneumatic systems where high pressure is unnecessary or could cause damage.

Key Features

- Precise Low-Pressure Control: Maintains consistent output pressure for sensitive applications

- Adjustable Pressure Range: Allows fine-tuning to meet system requirements

- Durable Construction: Available in stainless steel, carbon steel, alloy steel, and brass

- Automatic Regulation: Adjusts to upstream pressure fluctuations for stability

- Various Connection Types: Threaded, flanged, SW, and screwed end options available

Types of Low-Pressure Air Regulators

- Direct-Acting Low-Pressure Regulator – Simple design with a spring-loaded diaphragm

- Pilot-Operated Low-Pressure Regulator – Provides precise control for sensitive applications

- Adjustable Low-Pressure Regulator – Allows manual pressure setting for customization

- Fixed Low-Pressure Regulator – Pre-set for consistent low-pressure delivery

Applications

- Pneumatic Control Systems – Ensures stable low air pressure for automation

- HVAC & Ventilation – Maintains optimal airflow for climate control

- Medical Equipment – Provides controlled airflow for ventilators and oxygen systems

- Food & Beverage Processing – Used in controlled air supply for packaging and processing

- Painting & Spraying Systems – Regulates airflow for smooth, even spray application

Advantages

- Prevents Equipment Damage: Protects sensitive components from excessive pressure

- Ensures Efficiency: Delivers a stable air supply for smooth operation

- Enhances Tool Lifespan: Reduces wear and tear on pneumatic tools

- Energy Efficient: Minimizes air wastage and lowers operational costs

- Easy Installation & Maintenance: Simple to install, adjust, and replace when needed

Maintenance & Safety Tips

- Regular Pressure Checks: Monitor pressure readings to ensure stability

- Inspect for Leaks: Identify and fix any air leaks to maintain efficiency

- Clean the Regulator & Filter: Prevent debris from clogging the system

- Test for Functionality: Ensure smooth operation under different conditions

- Replace Worn Components: Change seals and diaphragms as needed for reliability