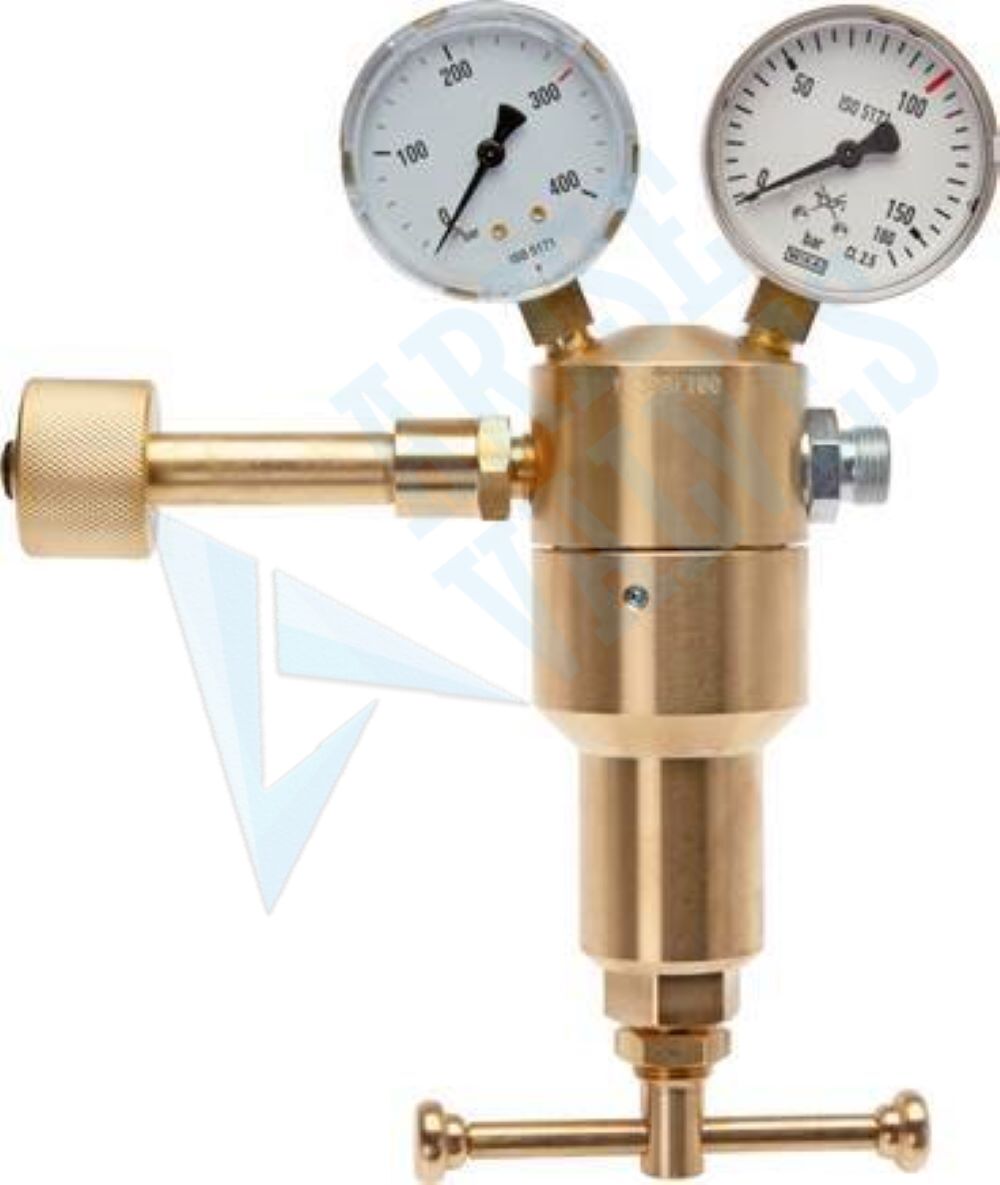

Lp pressure regulator

Low-Pressure (LP) Regulator

An LP pressure regulator controls and maintains a stable low-pressure output from a higher-pressure source, ensuring safe and efficient gas or fluid flow. It is commonly used in residential, commercial, and industrial applications for precise pressure regulation.

Key Features:

- Accurate Pressure Control – Maintains a steady low-pressure output for consistent performance.

- Durable Construction – Made from corrosion-resistant materials for long-term reliability.

- Compact & Lightweight – Designed for easy installation and space-saving applications.

- Adjustable Pressure Settings – Allows fine-tuning for specific system requirements.

- Built-in Safety Mechanisms – Prevents overpressure conditions and ensures safe operation.

Application:

- LPG & Natural Gas Systems – Used in home, commercial kitchens, and gas supply networks.

- HVAC & Heating Systems – Controls gas flow in furnaces, boilers, and water heaters.

- Industrial Gas Distribution – Ensures regulated pressure in manufacturing and processing plants.

- Medical Equipment – Used in oxygen and anesthesia gas delivery systems.

- Agriculture & Irrigation – Controls pressure in gas-powered irrigation systems.

Advantages:

- Enhances System Efficiency – Provides consistent pressure for optimal performance.

- Prevents Equipment Damage – Protects appliances from excessive pressure variations.

- Improves Safety – Reduces risks of leaks, explosions, and overpressure hazards.

- Reduces Gas Consumption – Optimizes fuel usage, lowering operational costs.

- Extends Equipment Lifespan – Minimizes wear and tear on connected components.

Maintenance & Safety Tips:

- Regular Inspections – Check for leaks, corrosion, and pressure fluctuations.

- Clean & Replace Filters – Prevents clogging and ensures smooth gas flow.

- Use Proper Installation – Ensure correct placement to avoid operational issues.

- Adjust Gradually – Prevent sudden pressure changes that may harm equipment.

- Follow Manufacturer Guidelines – Adhere to recommended servicing and safety protocols.