Steam regulator

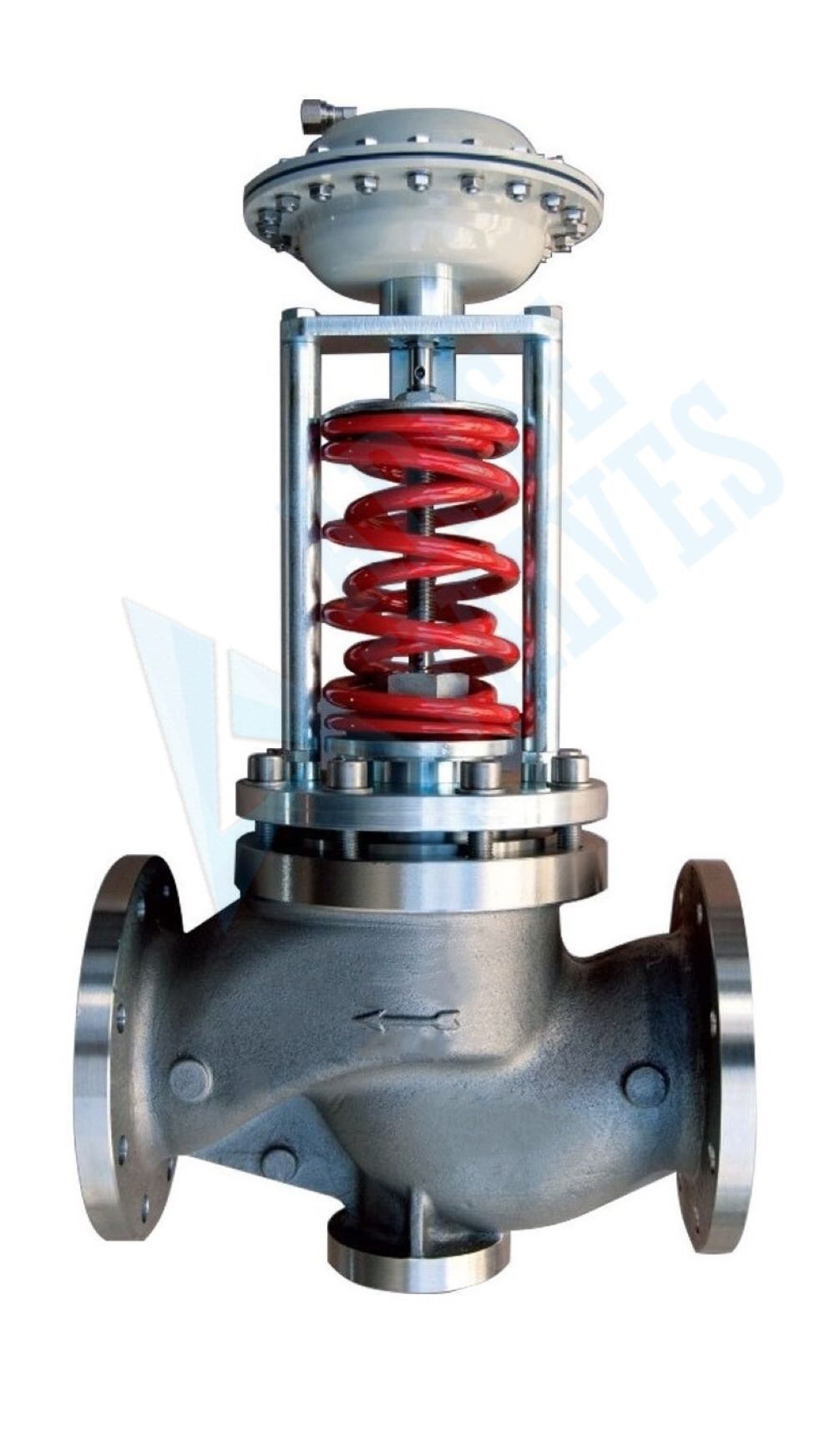

Steam Regulator

A steam regulator is a pressure control device used to maintain and regulate steam pressure within a system, ensuring safe and efficient operation of steam equipment.

Key Features

- Precise Steam Pressure Control: Maintains stable pressure for steam applications

- Automatic Operation: Adjusts steam flow based on system demand

- Multiple Connection Types: Threaded, flanged, SW, and screwed ends available

- High-Temperature Resistance: Designed for steam applications

- Available in Various Materials: Stainless steel, carbon steel, and alloy steel options

Types of Steam Regulators

- Direct-Acting Steam Regulator – Simple design with a diaphragm or spring for pressure adjustment

- Pilot-Operated Steam Regulator – Provides precise pressure control for high-capacity systems

- Self-Actuated Steam Regulator – Uses system pressure to regulate steam flow automatically

- Electric or Pneumatic Steam Regulator – Uses an actuator for automated control

Applications

- Boilers & Power Plants – Controls steam pressure in boilers

- Food Processing Industry – Regulates steam for cooking and sterilization

- Textile & Paper Industries – Manages steam usage in drying and processing operations

- Heating Systems & HVAC – Ensures stable steam supply in heating applications

- Chemical & Pharmaceutical Plants – Maintains precise steam pressure for industrial processes

Advantages

- Prevents Overpressure & System Damage: Enhances safety and equipment longevity

- Improves Energy Efficiency: Reduces steam wastage and optimizes performance

- Provides Consistent Steam Flow: Ensures smooth operation in industrial processes

- Adjustable Pressure Settings: Customizable for different steam applications

- Durable & Reliable: Built to withstand high temperatures and pressures

Maintenance & Safety Tips

- Regular Pressure Checks: Ensure optimal steam pressure levels

- Inspect for Leaks & Corrosion: Prevent system failures by addressing wear and tear

- Clean Valves & Pipes: Avoid blockages that may affect performance

- Ensure Proper Installation: Use high-temperature seals and fittings

- Follow Manufacturer Guidelines: Adhere to pressure and temperature limits for safety